The bigger the aircraft, the more systems you’ll find — especially when it comes to twin engine aircraft systems.

Every twin aircraft is equipped with complex mechanisms designed to improve safety, performance, and redundancy. From propeller governors to hydraulic and deicing systems, understanding how these twin engine aircraft systems work helps pilots operate more efficiently and handle in-flight emergencies with confidence.

1) Propeller governors

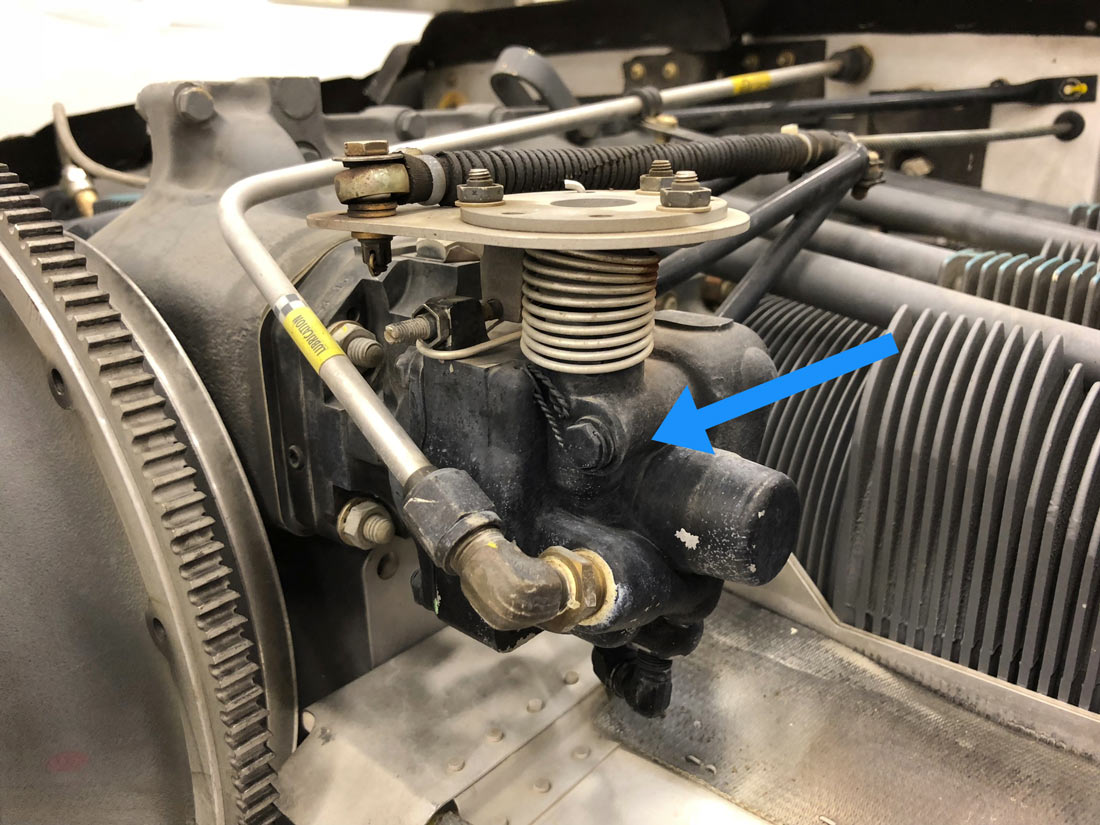

The propeller governor is responsible for changing the pitch of the propeller, based off of pilot inputs and changing engine/propeller workloads. It works to maintain a constant engine RPM in flight.

2) Squat switches

These squat switches, or “weight-off-wheels” switches are responsible for activating or deactivating systems while on the ground. Squat switches may turn off lift detectors on the ground, turn off maintenance hobbs time, and prevent inadvertent gear retraction.

3) Unfeathering accumulators

Found in many multi-engine training aircraft, the unfeathering accumulator stores oil under pressure when you move a propeller lever into the feather detent position. When you move the propeller back out of detent, high pressure oil returns to the propeller hub, moving the propeller blades back toward low pitch/high RPM. This helps the propeller start windmilling again, and helps the engine to restart.

4) Advanced environmental controls

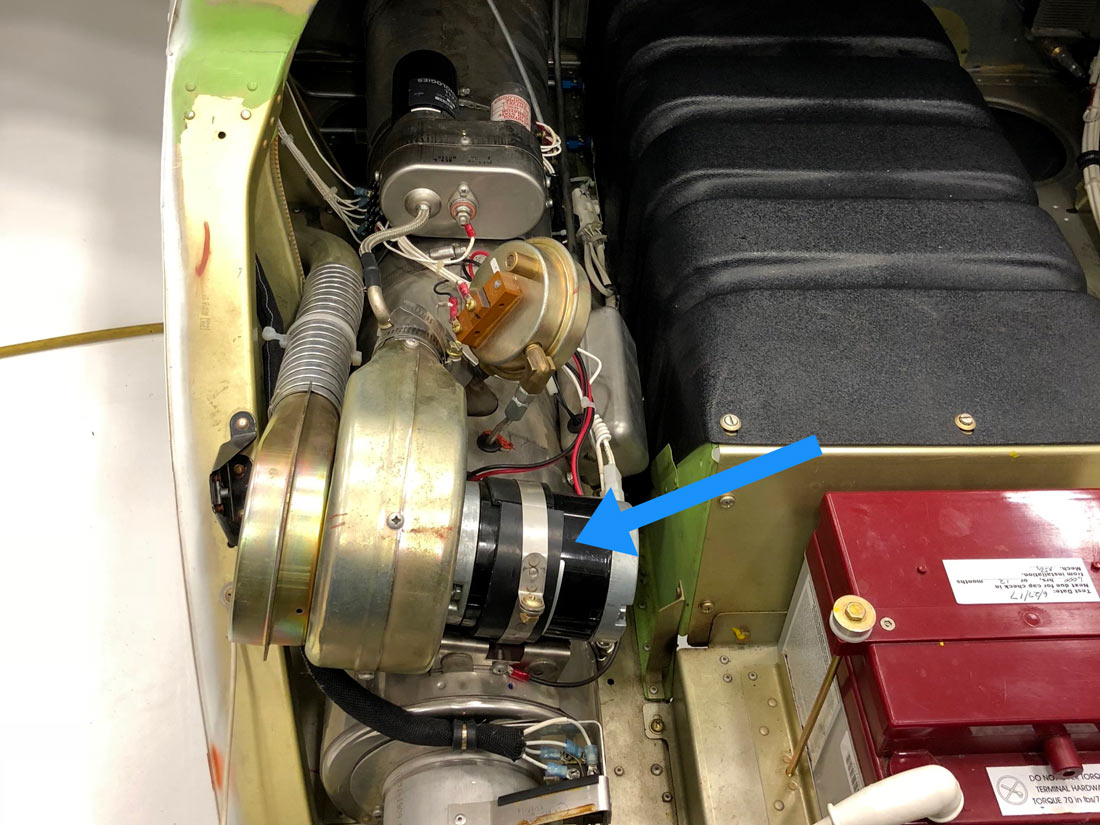

Among the most overlooked twin engine aircraft systems are the advanced environmental controls that keep pilots and passengers comfortable in all seasons. Systems like the 35,000+ BTU Janitrol or C&D combustion heater burn fuel in a sealed cylindrical chamber to provide consistent cabin heat even at high altitudes.

These heaters operate independently from the engines, ensuring reliable warmth during long winter flights. In addition to heating, twin aircraft often feature ventilation and defog systems that circulate warm or cool air to maintain visibility and comfort. Proper understanding and maintenance of these environmental systems are essential for both safety and efficiency during cold-weather operations.

5) Hydraulic systems

Most aircraft use hydraulics to raise and lower landing gear. And in larger aircraft, the hydraulic system can be routed to manipulate control surfaces, like ailerons and flaps.

6) Synchrophasers

Synchrophasers are an important part of modern twin engine aircraft systems, responsible for matching the propeller RPM of both engines to minimize vibration and cabin noise. When the propellers are even slightly out of sync, they create a rhythmic “wha-wha-wha” sound that can quickly become uncomfortable during flight.

The synchrophaser automatically adjusts propeller pitch or RPM to bring both engines back into perfect harmony, making the aircraft quieter, smoother, and more efficient. This system not only improves passenger comfort but also reduces wear on engine components caused by uneven torque and vibration.

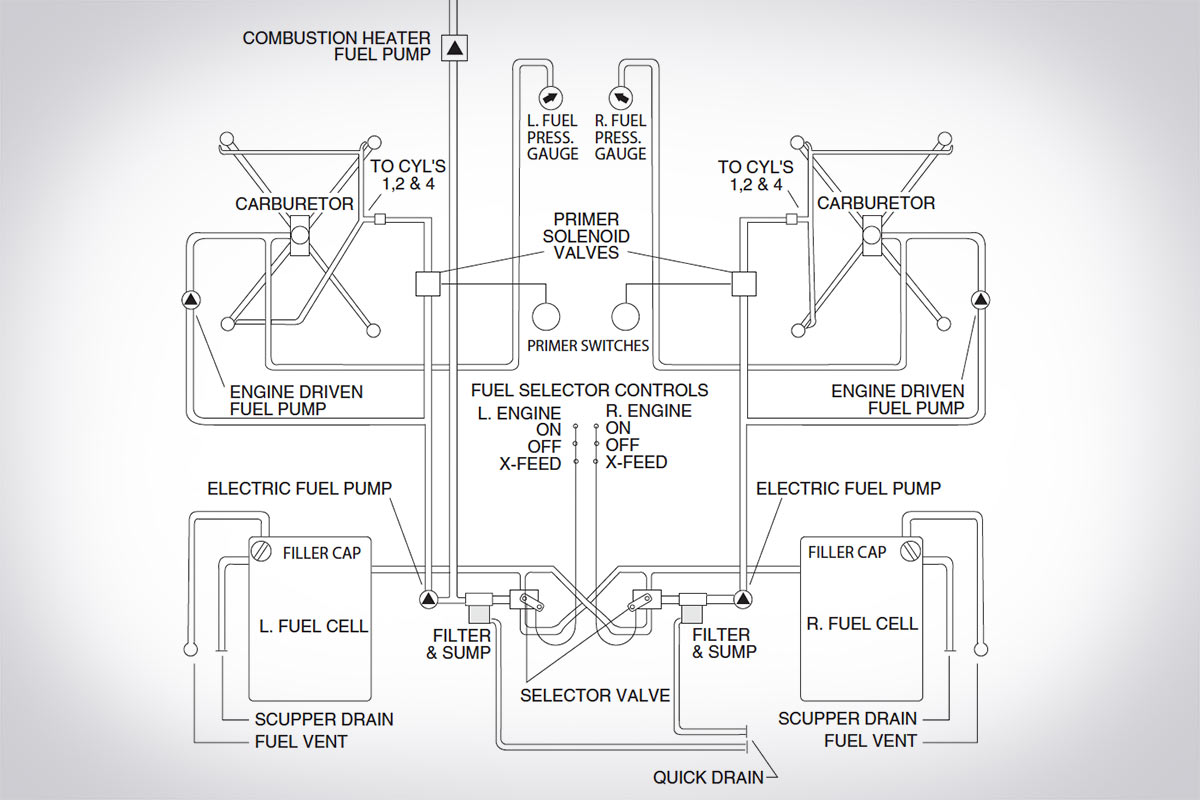

7) Fuel cross-feed

A fuel imbalance can easily be solved by switching the fuel selector of the lowest tank to cross-feed. This allows an engine to draw fuel from the opposite fuel tank.

8) Deicing/anti-icing equipment

Whether it’s deicing boots, weeping wings, or heated leading edges, there are several types of deicing equipment you can find on complex twin-engine aircraft. These systems are among the most important twin engine aircraft systems, as they directly affect safety and aircraft performance in freezing conditions.

Pneumatic boots inflate and break ice from the leading edges, while thermal systems use electric or bleed-air heat to prevent ice formation altogether. In some advanced designs, fluid-based “weeping wing” systems continuously release a thin layer of antifreeze over the surface to reduce ice accumulation. Understanding how these deicing and anti-icing components work together helps pilots maintain lift, reduce drag, and ensure full control of their twin aircraft in adverse weather.

If you’d like to learn more about handling in-flight issues and common malfunctions, read also about Twin-Engine Troubles.